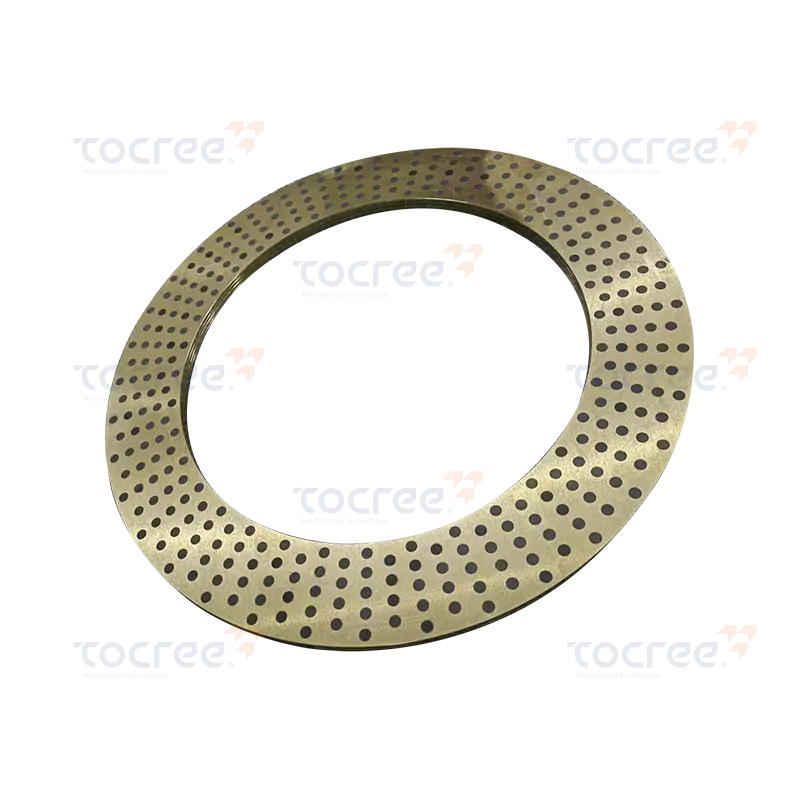

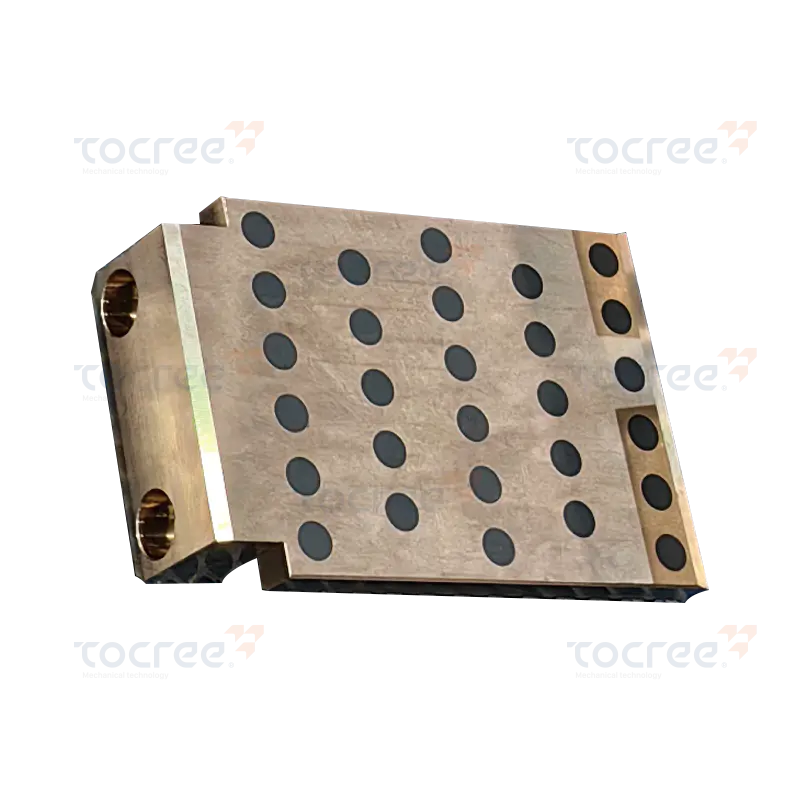

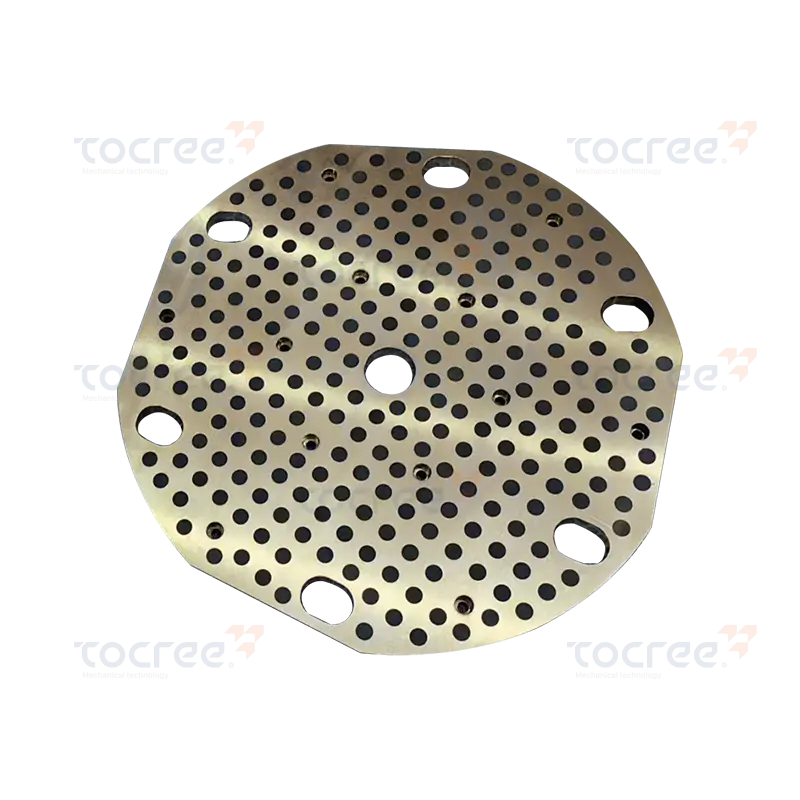

Material structure: Cast aluminum bronze CuZn25Al6Fe3Mn3, with graphite insert. Applicatio...

Bronze Bushing

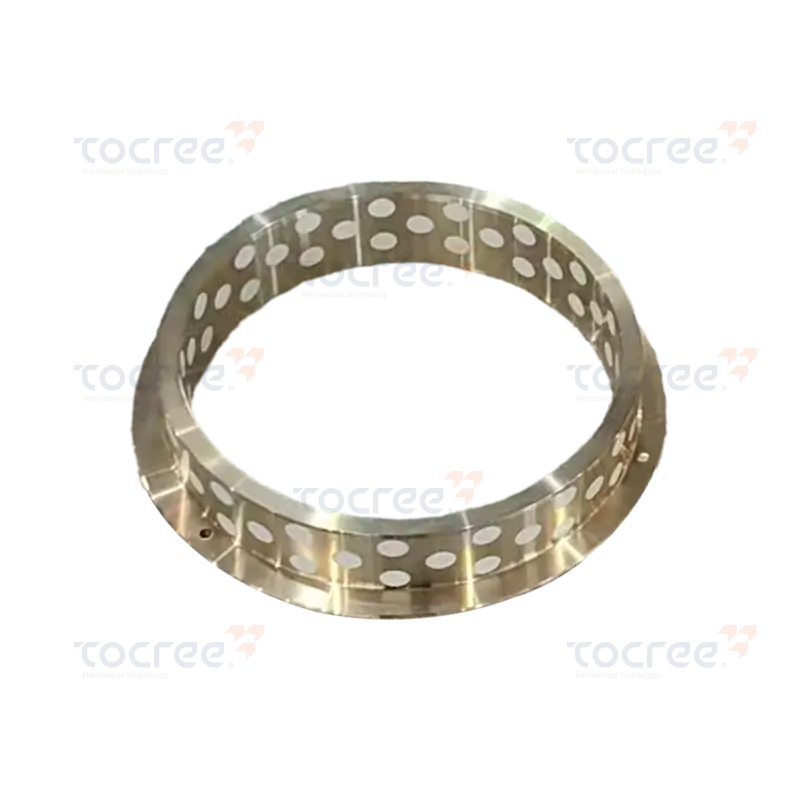

This bronze sleeve is made of tin bronze as the base material. The blank piece is produced through centrifugal casting process. Then, according to the customer's requirements, multiple oil grooves are machined on the inner and outer working surfaces of the sleeve for precise processing. This product has excellent mechanical properties, wear resistance and corrosion resistance, and is highly suitable for industrial applications that require high durability, corrosion resistance and high strength.

High tensile strength: The tensile strength exceeds 260 MPa, ensuring stability and durability under heavy load conditions.

Good yield strength: The yield strength exceeds 120 MPa, suitable for continuous pressure without deformation.

Excellent elongation: Good elongation (≥12%), enhancing impact resistance and fatigue performance.

High hardness: The hardness is 70 HB, effectively resisting external wear.

Resistance to wear and corrosion: The addition of tin and lead significantly improves wear and corrosion resistance.

Optional oil groove design: Customizable inner and outer oil grooves according to different application requirements.

|

Material |

747 tin bronze ZCuSn7Zn4Pb7 |

|

Mechanical properties |

|

|

Tensile strength |

260 MPa |

|

Yield strength |

120 MPa |

|

Elongation |

12% |

|

Hardness |

70 HB |

-

Welcome to the industry’s global hotspot! Conference Dates: April 20-24, 2026 Booth: Hall 13 G06-3 The world's leading trade fair for the manufacturing industry. All key technologies and core are...

READ MORE -

Tocree has invested in a CY-K80N/3000 heavy-duty CNC lathe, boosting our ability to produce long-length copper alloy parts (up to 3000mm) with a maximum outer diameter of 200mm. This upgrade means we’...

READ MORE -

December 2025 – Tocree (Tocree Machinery) has further strengthened its precision machining capabilities and product accuracy with the introduction and commissioning of a new advanced high-precision CN...

READ MORE -

November 2025 – To meet continuously growing market demand, Tocree (Tocree Machinery) has officially launched and completed a significant expansion of its core foundry workshop. The project added 1,30...

READ MORE -

In early July 2025, TOCREE successfully completed the relocation of its production and operational base. The company has moved from its former location at Room 101, Building 27, Jiashan Information Te...

READ MORE

English

English