For any questions and feedback from customers, we will reply patiently and meticulously.

Material structure: Cast aluminum bronze CuZn25Al6Fe3Mn3, with graphite insert. Application features...

November 2025 – To meet continuously growing market demand, Tocree (Tocree Machinery) has officially launched and completed a significant expansion of its core foundry workshop. The project added 1,300 square meters of production space to the existing workshop, bringing the total area to 3,800 square meters. The expansion included the installation of six additional advanced melting furnaces and supporting equipment, driving a substantial leap in production capacity. Upon full operation, the company's overall output of copper alloy castings is projected to increase by more than one-third.

This large-scale expansion represents a major release of production capacity in the upstream casting segment, following the optimization of the overall layout at Tocree's new factory. The enhanced melting capability and additional production space will directly support the blank casting production of various brass, bronze, and other copper alloys, supplying a more abundant and high-quality inventory of blanks for subsequent precision machining processes. This advancement will significantly shorten manufacturing lead times and markedly strengthen the company's ability to fulfill large-scale and urgent orders.

As the starting point of the company's integrated "casting + machining" industrial chain, the capacity and stability of the foundry are crucial to ensuring the final product performance and delivery reliability. This investment and expansion underscore Tocree's strong confidence in market prospects and its long-term commitment to serving customers by reinforcing fundamental manufacturing capabilities. The company expects the new capacity to be fully operational by early 2026, enabling a more efficient and flexible production system to continue providing stable and high-quality copper alloy components for global partners in sectors such as engineering machinery, automation equipment, and shipbuilding.

New Factory Address: No. 18 Zhensheng Road, Weitang Street, Jiashan County, Jiaxing City, Zhejiang Province, China

Material structure: Cast aluminum bronze CuZn25Al6Fe3Mn3, with graphite insert. Application features...

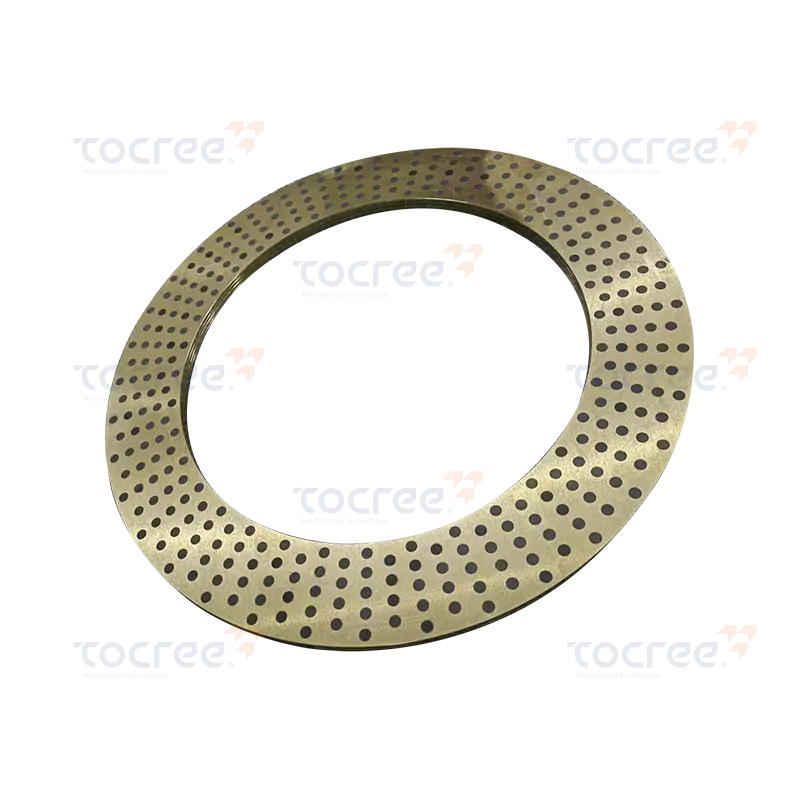

Solid self-lubricating copper rings are high-performance components, made by precision machining wit...

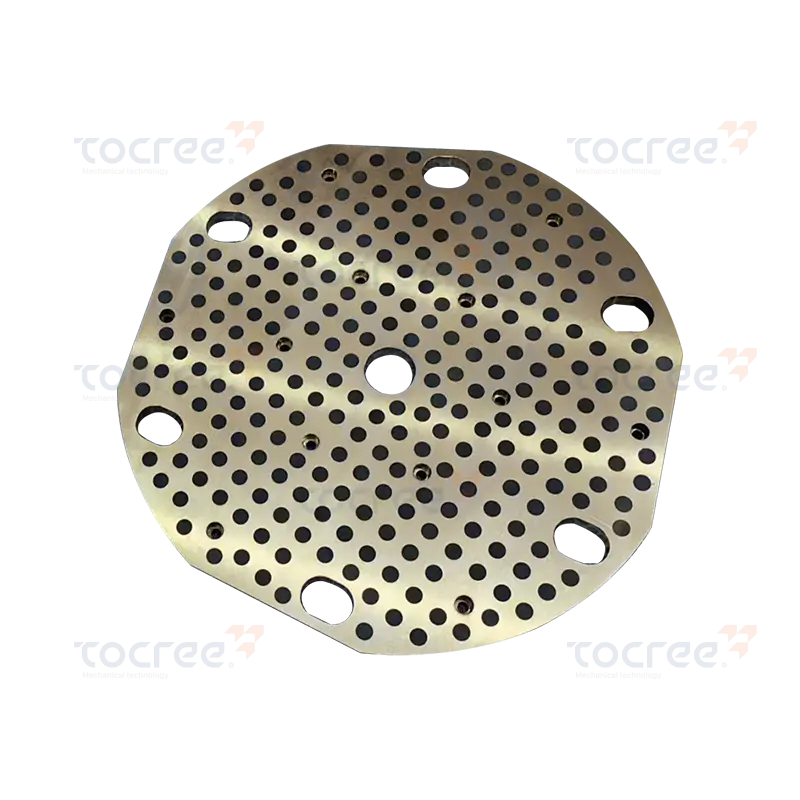

The octagonal bushing made of CuSn6Zn6Pb3 (tin bronze) and graphite precision machining is a self-lu...

The PTFE single-flange solid self-lubricating copper sleeve is a high-performance mechanical compone...

Single-flange self-lubricating bearing (with graphite embedding) is a high-performance solid self-lu...

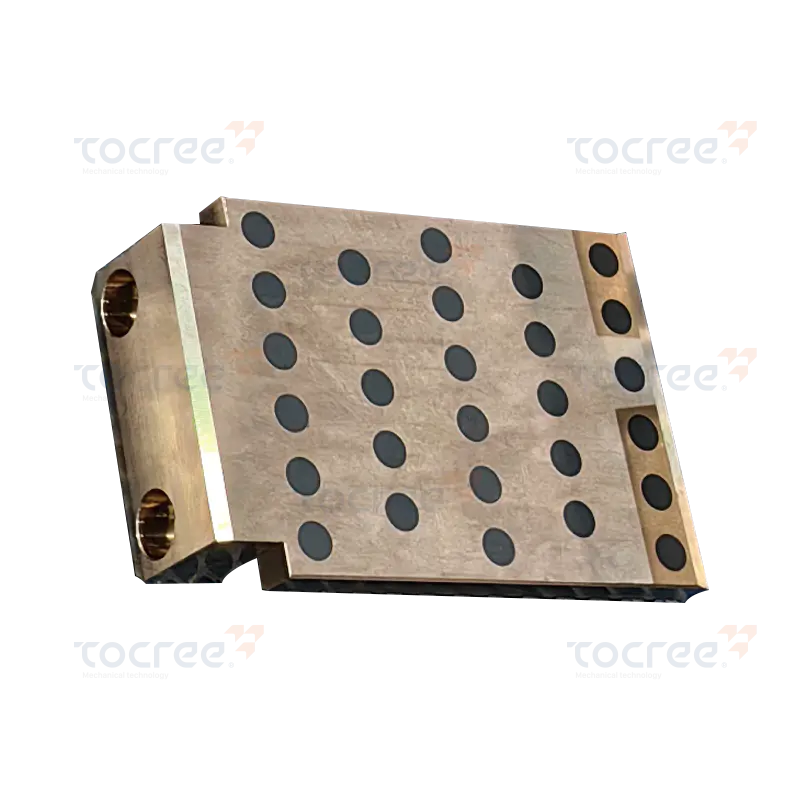

The L-shaped solid self-lubricating slider is made by embedding high-purity graphite solid lubricant...

This spherical self-lubricating copper sleeve is made from high-strength high-strength brass as the ...

The copper-based graphite gasket is made of high-quality copper-zinc alloy as the base material. Its...

For any questions and feedback from customers, we will reply patiently and meticulously.