For any questions and feedback from customers, we will reply patiently and meticulously.

6,600㎡ Constant Temperature Smart Manufacturing System: Tech & Scale Drive Quality, Green & Low-Carbon Empower Sustainable Development.

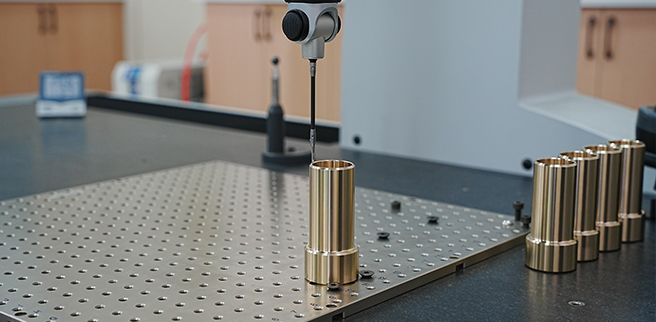

Tocree Precision Machining Base boasts a 6,600㎡ full-scenario constant temperature workshop with precise 20±3℃ control, covering core machining, deburring & chamfering, graphite inlaying and all processes, eliminating precision & material stability issues caused by temperature variation. The intelligent temperature control system enables real-time monitoring, auto-adjustment and remote alert of temperature & humidity to cut energy consumption. The 6,600㎡ standardized production line balances mass production efficiency and quality control, ensuring product consistency.

-

Consistent StabilitySetting a new benchmark for "stability"

Consistent StabilitySetting a new benchmark for "stability"Constant temperature control shields the production environment from seasonal and day-night temperature fluctuations, minimizing batch-to-batch variations in casting performance.

-

Precision ControlA "microclimate" that exceeds standard precision

Precision ControlA "microclimate" that exceeds standard precisionBy regulating the solidification environment at a micro-level, we reduce thermal shock, achieving finer grain structures and superior mechanical properties.

-

Traceable QualityEnvironmental parameters recorded throughout the entire process

Traceable QualityEnvironmental parameters recorded throughout the entire processData from the constant-temperature system is linked to each production batch, providing an additional layer of traceability assurance for product quality.

English

English